The introduction of mega and gigacasting processes is changing the automotive industry: single-piece structural components such as front or rear undercarriages and battery housings made of die-cast aluminium are replacing hundreds of individual components that have to be welded. This technology, used by Tesla and Volvo, for example, simplifies production, reduces weight and improves the rigidity of the components. At the same time, it places new demands on the post-processing of cast parts.

Aulbach Automation abk Pressenbau, based in Mömlingen in Lower Franconia, understands this. The company, which has 70 employees, specialises in the manufacture of highly specialised deburring presses for the foundry industry. In 2021, it entered the mega and gigacasting segment, i.e. the processing of large castings with dimensions exceeding 3 x 2.5 metres and shot weights of 80 to 120 kilograms. "The decision at the time was bold and risky – because we started without a single order. That's why we are now one step ahead of the competition," says Managing Director Ulrich Krimm.

Today, Aulbach Automation claims to be the market leader in deburring presses for large castings and has delivered 23 deburring presses for megacasting by September 2025 alone.

The combined offer of presses and dies from a single source has contributed to this success. Most of the international customers, who mainly come from the automotive and mechanical engineering industries, take advantage of this offer.

Together with its sister company Aulbach Entgratungstechnik, the machine manufacturer offers complete solutions that are perfectly coordinated. "We know and master the entire process," emphasises Krimm. "This combination is unique and gives us a decisive competitive advantage."

The construction time for a customised press is around 35 weeks. Since development, design, welding, painting, switch cabinet construction and assembly of the presses, as well as diemaking, all take place at the same location, coordination channels are short.

The focus of modern deburring presses is increasingly on the ergonomics, safety and efficiency of die changing – a core competence of ROEMHELD, the set-up time optimiser based in Laubach in central Hesse. This is because one of the key challenges in deburring large castings is the safe and precise handling of dies weighing up to 30 tonnes. Automated solutions are the first choice in terms of occupational safety and productivity, given the dimensions and weights involved. They are standard in fully automated plant concepts such as complete megacasting die-casting plants.

Depending on requirements, the dies are brought to the press by crane or transport trolley, lifted onto ROEMHELD hydraulic transport bars by vacuum suction cups or robots, and then precisely inserted into the press, where they are positioned and clamped. Removal takes place in reverse order.

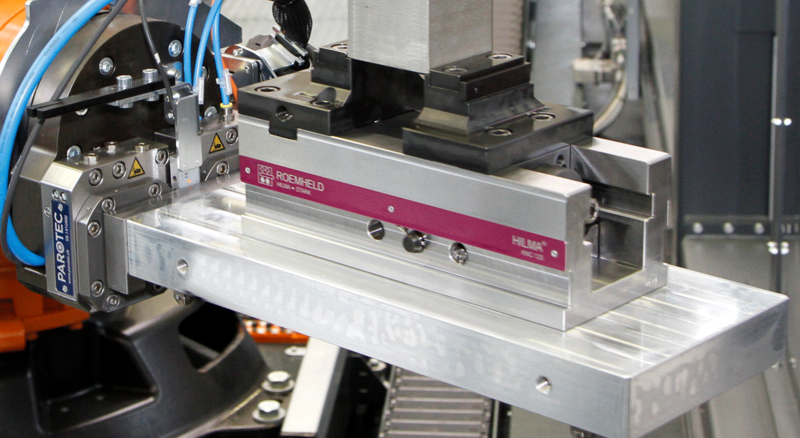

For over ten years, Aulbach Automation has been using die clamping and changing systems from the ROEMHELD Group. Since then, the components from the clamping technology specialist – in particular powered die changing systems, ball and roller bars, and die clamping elements – have been installed as standard on the large-format deburring presses.

"In our view, there are many reasons to choose these products: their precision, short delivery times, reliability, durability, excellent coordination of the elements with each other and impressive service. All this makes ROEMHELD an ideal partner for us," explains André Pfeifer, Technical Project Manager at Aulbach Automation.

He cites a megacasting plant from the Swiss Bühler Group as an example of success. In 2022, it delivered two complete die casting plants, including an Aulbach deburring press, equipped with die clamping and changing technology from ROEMHELD to a Volvo Cars production plant in Sweden.

As with most deburring presses that Aulbach Automation equips with ROEMHELD components, hydraulically double-acting swing sink clamping elements are used on the press table.

"Despite their compact design, they achieve clamping forces between 60 and 412 kilonewtons," explains Pfeifer. This allows clamping edge tolerances of ±1.5 millimetres to be compensated and even hard-to-reach areas to be clamped securely.

"The force is transmitted efficiently because the clamping piston is moved in such a way that a 45° rotation is performed simultaneously during a stroke phase. This allows the dies to be inserted safely and without interference edges."

The special feature of the clamping system is its high operational reliability: the release, switchover and clamping positions are monitored inductively, and the swing sink mechanism is additionally protected by a spring-loaded overload protection device and a manual emergency control.

To facilitate the insertion and removal of heavy dies, ROEMHELD transport rails are also integrated into the table surface.

90° swing sink clamps are used on the press ram, which are equipped in the same way as the clamping elements on the press table. "The ROEMHELD clamping technology in the press ram and press table ensures that even large-format, heavy dies are reliably fixed and held in position – crucial for process reliability and repeat accuracy in megacasting," emphasises Pfeifer. The tolerances of the clamping solution are a few tenths of a millimetre, which easily meets the required component tolerances.

All clamping elements are driven centrally by a ROEMHELD hydraulic unit, whose output is matched to the components. The modular element controls and monitors all functions. An energy-saving standby mode is automatically activated during production interruptions.

The clamping technology control system is integrated into the machine control system of the deburring press. It is based on a Siemens control system, which has been equipped with its own intuitive user interface by Aulbach Automation, and enables quick access to all processes.

The advantages of automated die change include reduced set-up times and increased process reliability. For the operator, the most important factors are improved ergonomics and safety when working on the press. While the frequency of die changes in the megacasting sector is typically low, the quality of the changeover process is paramount. Inaccurate positioning or incorrect clamping of dies can damage them and lead to faulty components, causing expensive production downtime.

In order to create the conditions for further growth, Aulbach Automation has built a new assembly hall with a 63-tonne crane capacity in 2024, where the large presses can be assembled in a standing position.

Krimm expects international demand for ever larger Megacasting deburring presses to grow steadily in the future. The machine manufacturer is therefore planning to expand the press sizes beyond the current dimensions. "We are also seeing that our customers' requirements are becoming increasingly individual," says the managing director. "In future, specific adaptations will certainly be necessary more often. With ROEMHELD as our partner, we are confident that together we will develop solutions that meet our customers' high expectations."

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Aproveche nuestra zona de login gratuita:

- Descarga de datos CAD

- Descarga de instrucciones de servicio

¡Bienvenido de nuevo! Inicie sesión con su cuenta de usuario ya existente.'